| Provider | WÖHR Autoparksysteme GmbH |

| Purpose | Essential cookies enable basic functions and are necessary for the proper functioning of the website. |

| Privacy Statement | https://woehr.de/de/datenschutz.html |

| Names | PHPSESSID, csrf_contao_csrf_token, csrf_https-contao_csrf_token |

| Lifetime | When ending the browser session. |

Comparisons

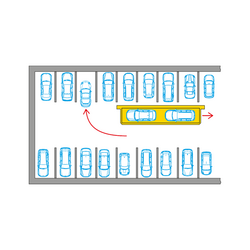

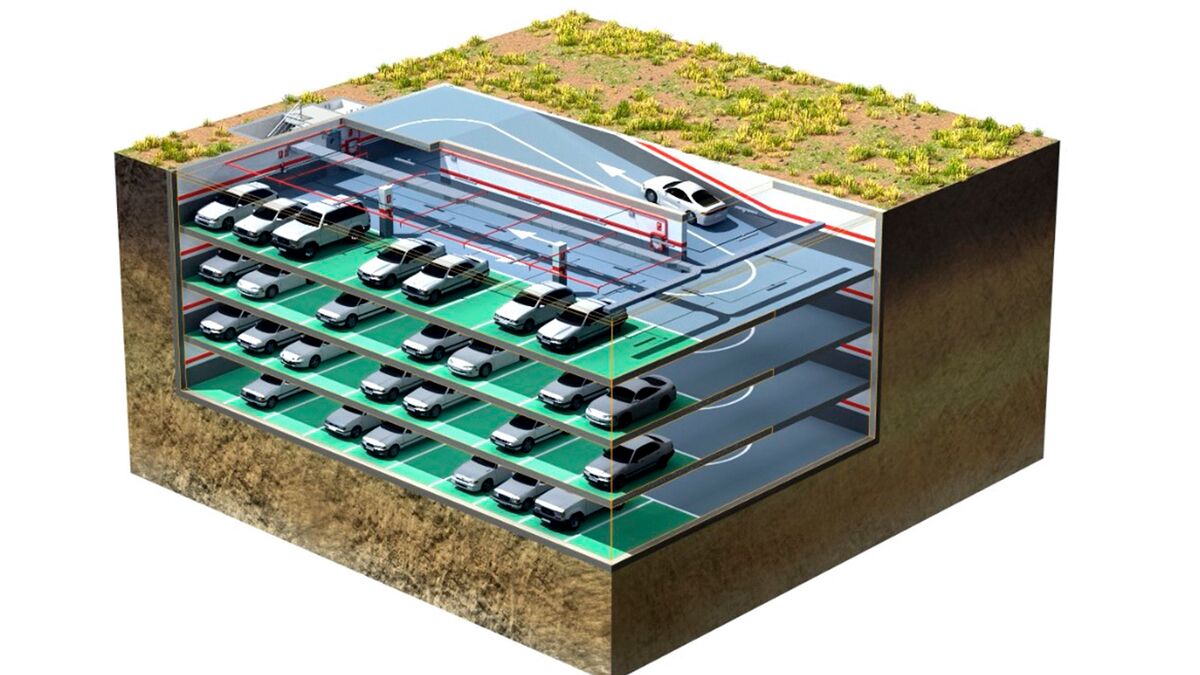

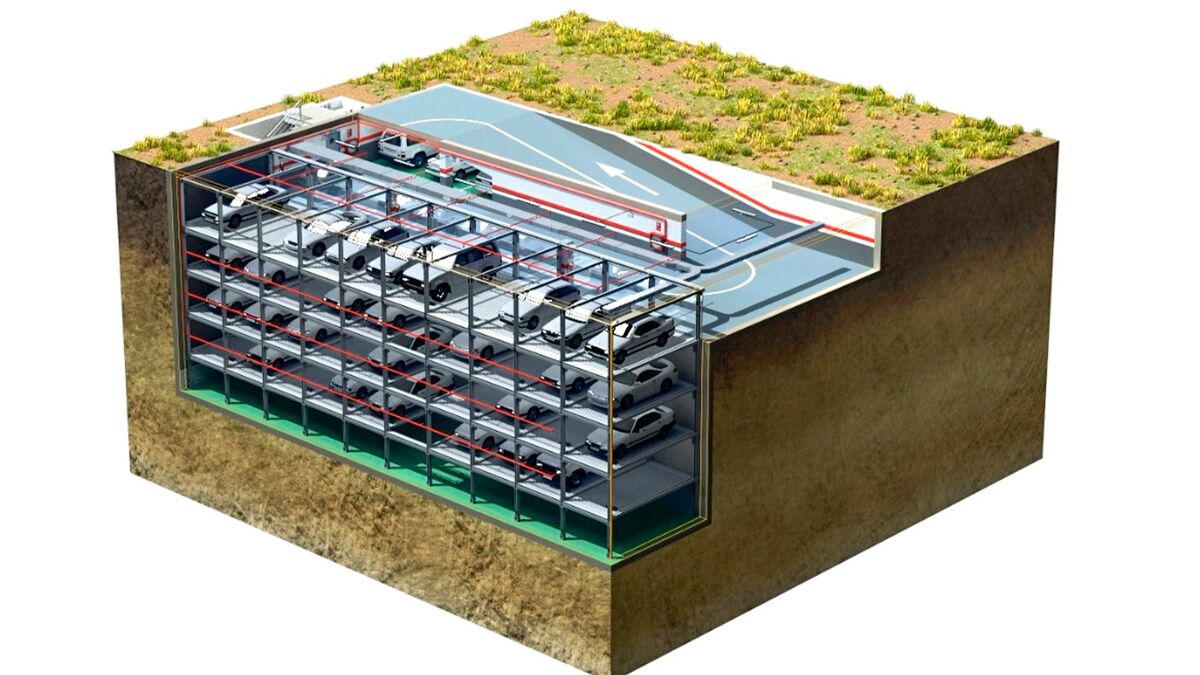

Conventional underground car parks versus parking systems

The following comparison between conventional underground car parks and our car parking system solutions illustrates the differences in space and volume required, material use, energy consumption, emissions and costs.

We compare two solution approaches (one conventional and one using parking systems) with the same or similar conditions and requirements. Our assumptions are based on an identical plot size and total number of parking spaces.

Based on these requirements, we design an optimal design for both systems, which allows us to compare both. As a basis for the comparison, we assume a fictitious plot for an apartment building of approx. 33 m by 19 m. The total construction area is around 640 m2.

The conventional underground car park has the same area, but requires the creation of a second storey with a second ramp to accommodate the same number of parking spaces.

In general, the volume of the conventional underground car park is significantly larger than the solution using parking systems.

The first level is 3.3 m deep with an additional 2.4 m for each additional storey. The first level of an underground car park must be at least 3.3 m deep underground to provide sufficient space for technical installations such as ventilation systems, fire extinguishing systems and storage space for any other necessary installations. These systems are necessary to ensure the safety and functionality of the underground car park.

*All dimensions are based on the Recommendations for Systems for Stationary Traffic 2023 (Empfehlungen für Anlagen des ruhenden Verkehrs 2023 (EAR 23)) of the Road and Transportation Research Association (FGSV).

Comparison with a conventional underground car park

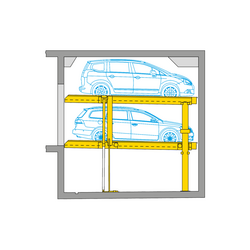

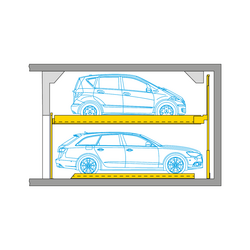

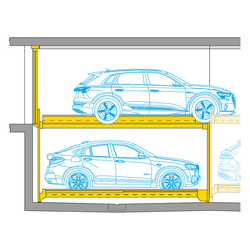

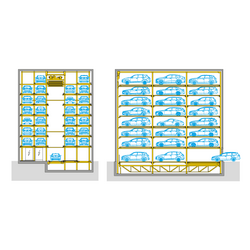

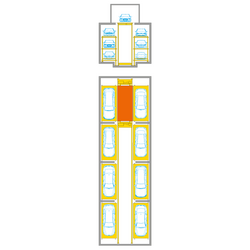

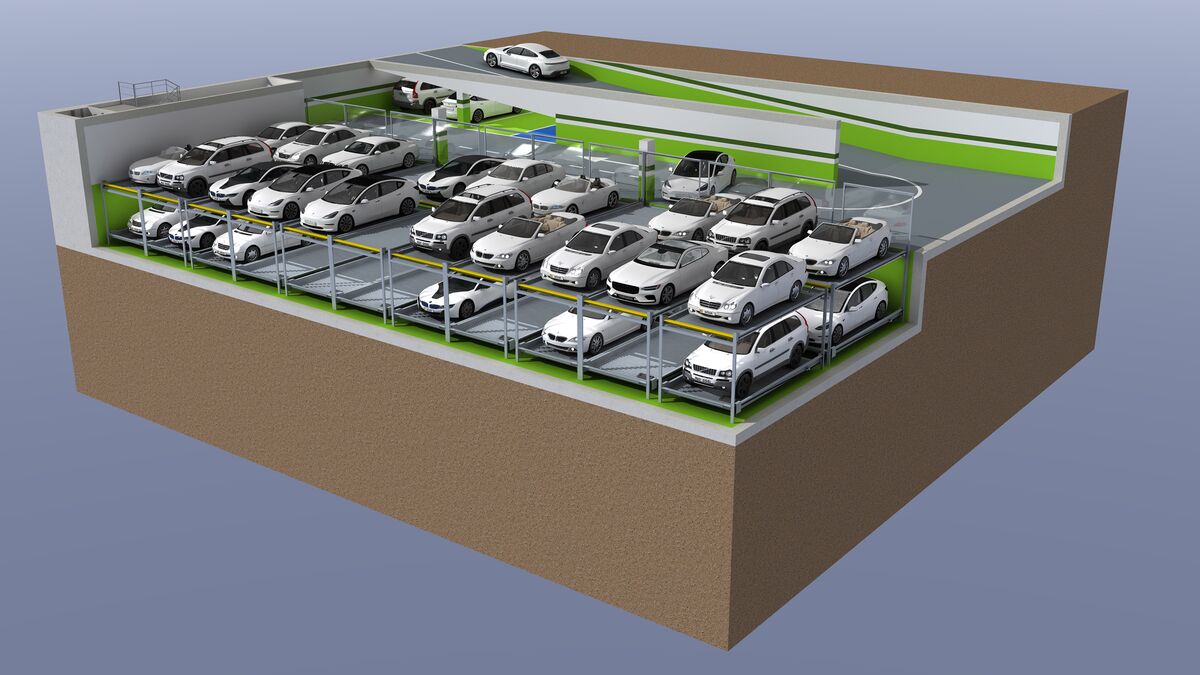

PARKLIFT 450

The Parklift 450 parking system is designed for independent parking of 2 cars on top of each other. To enable independent parking, the Parklift 450 requires space for 3 levels as the platforms have to move up and down.

-

Surface area

Width 19,05 m x length 33,70 m at approx. 642 m²

-

Underground levels

2

-

Parking spaces Parklift

24

-

Parking spaces Conventional underground car park

27

-

Parking Space Parking system

Length 5,50 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

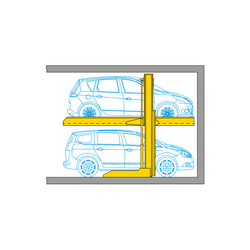

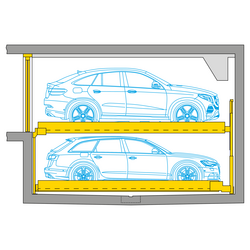

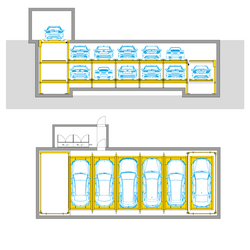

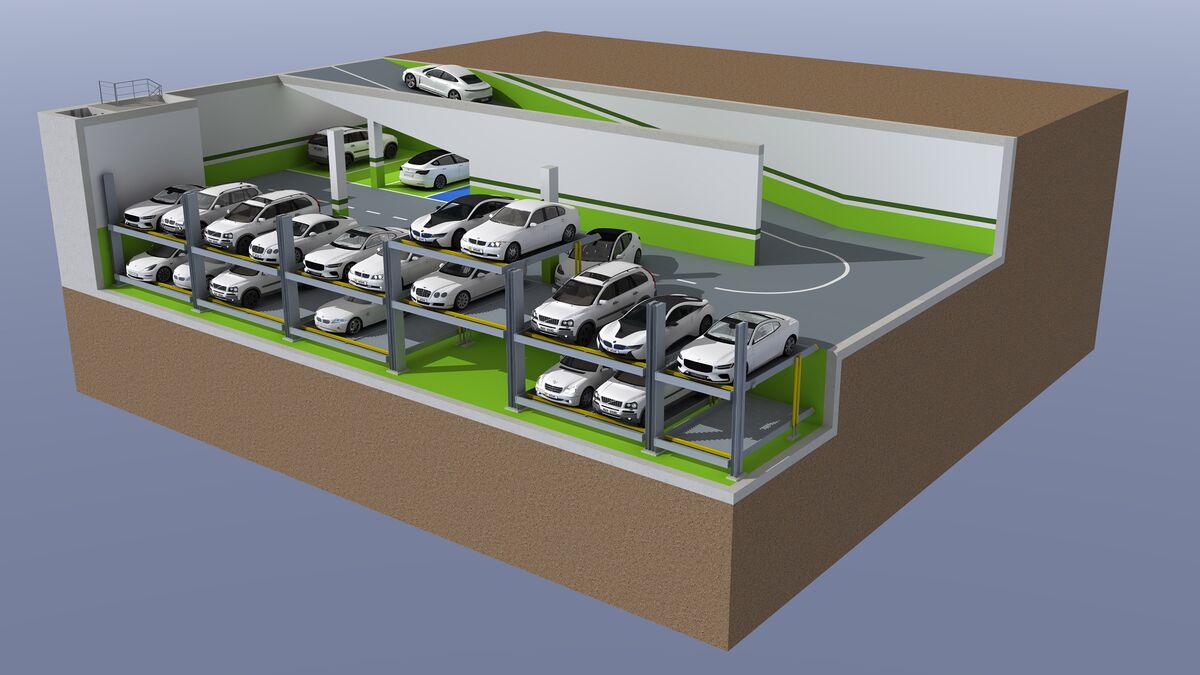

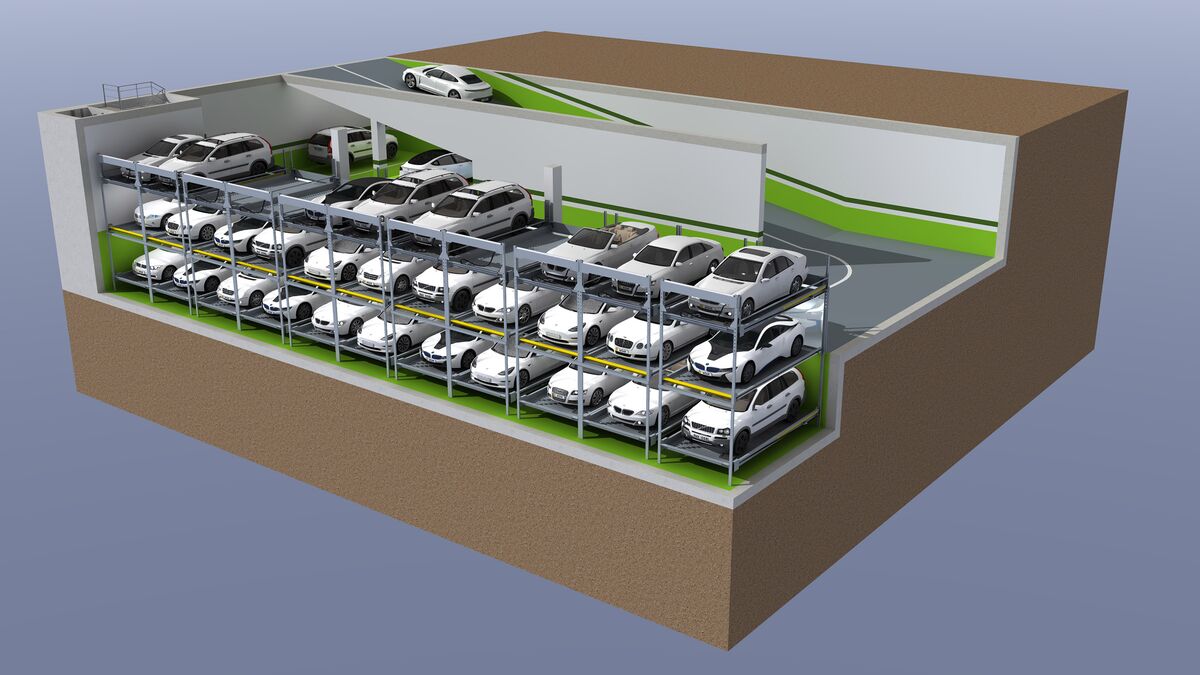

COMBILIFT 542

With the ´Combilift 542´, the vehicles are stored in an extremely compact way by raising, lowering and moving the parking pallets sideways, and can still be parked independently.

-

Surface area

Width 19,05 m x length 33,70 m at approx. 642 m²

-

Underground levels

2

-

Parking spaces Combilift

25

-

Parking spaces Conventional underground car park

27

-

Parking Space Parking system

Length 5,50 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

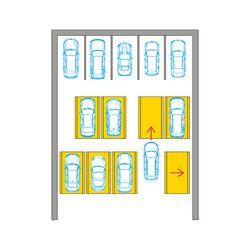

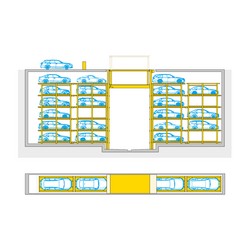

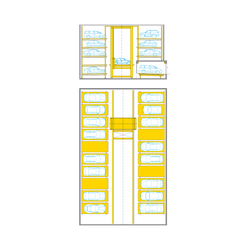

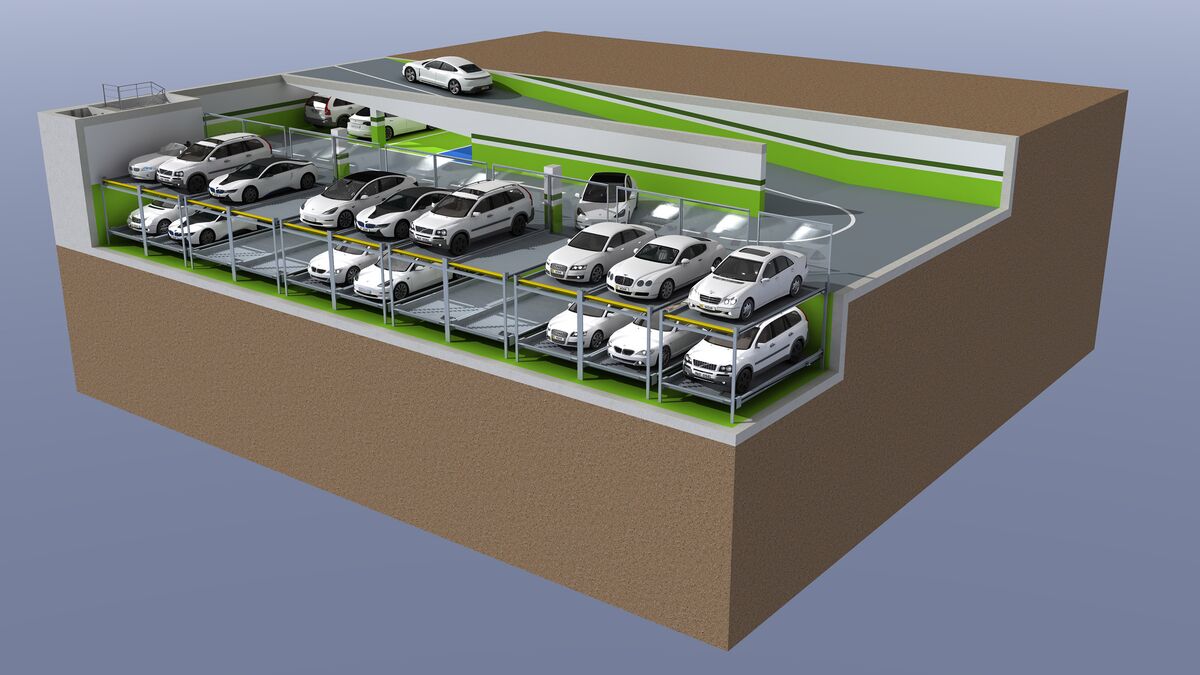

COMBILIFT 542 MR

With the ´Combilift 542MR´, the vehicles are stored in an extremely compact way by raising, lowering and moving the parking pallets sideways, and can still be parked independently.

Thanks to the ‘Multi Row’ function of the MR version, the systems and therefore also the vehicles can be arranged in multiple rows. The flexible MR sliding platform acts as a bridge and enables access to the rear row of the parking system.

-

Surface area

Width 24,85 m x length 33,70 m at approx. 837 m²

-

Underground levels

2

-

Parking spaces Combilift

46

-

Parking spaces Conventional underground car park

39

-

Parking Space Parking system

Length 5,70 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

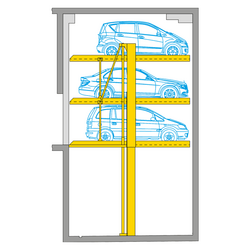

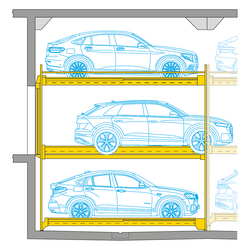

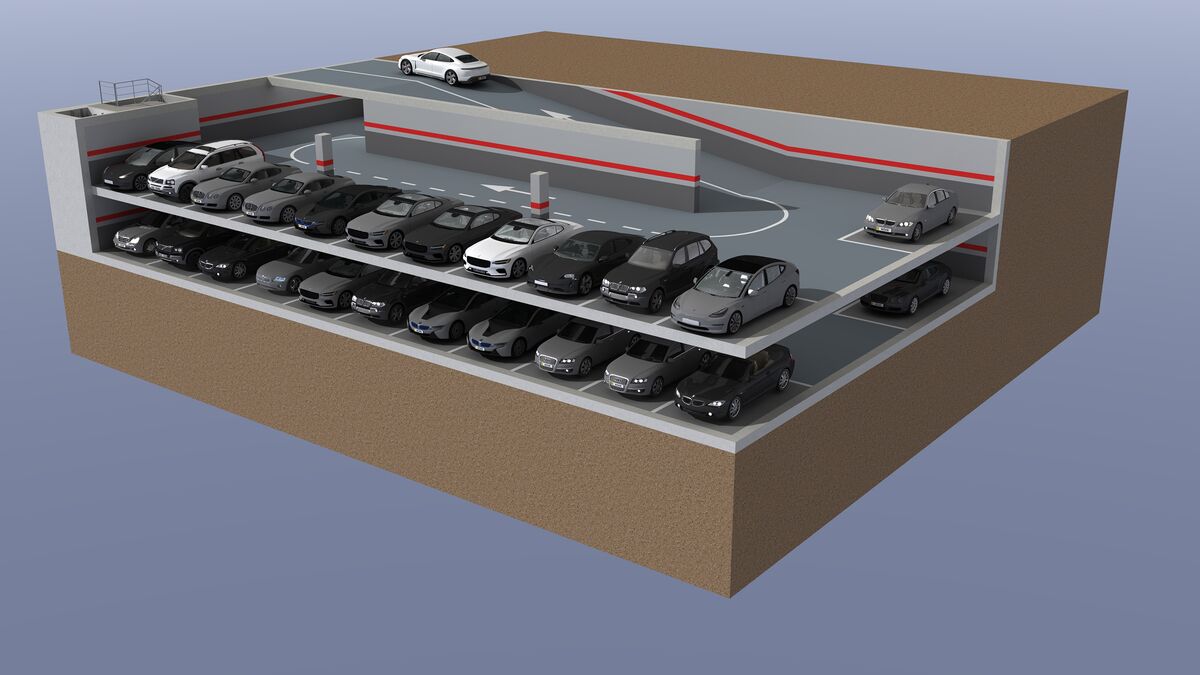

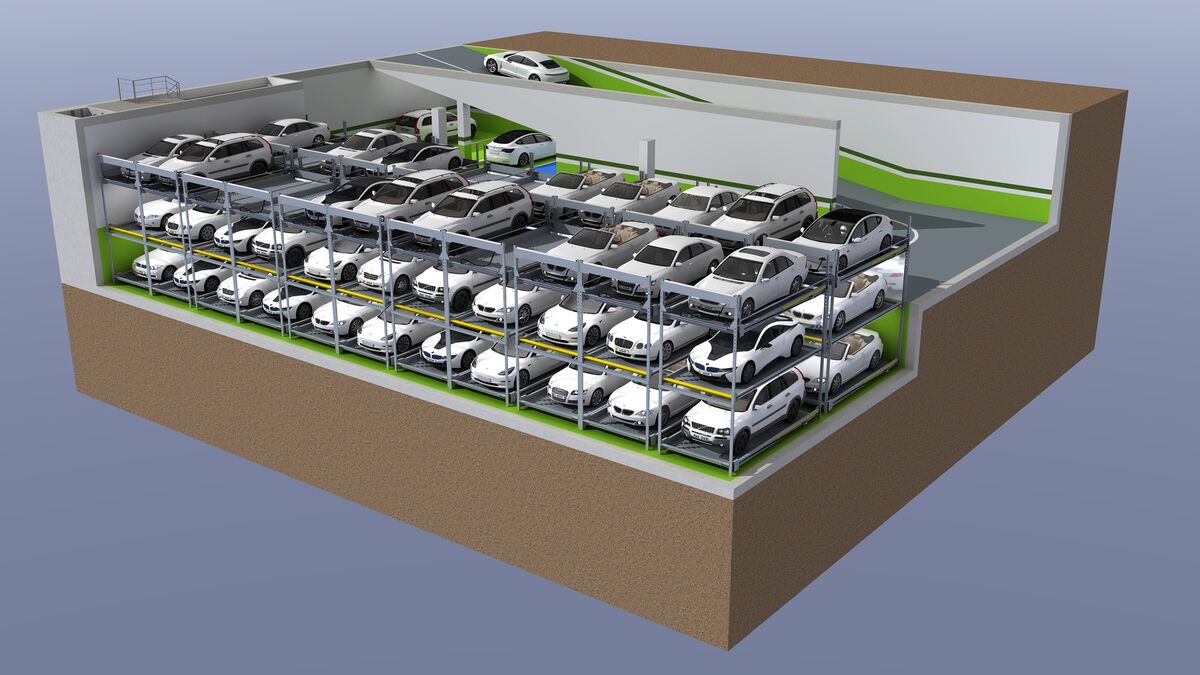

COMIBLIFT 543

With the ‘Combilift 543’, the vehicles are stored in an extremely compact way by raising, lowering and moving the parking pallets crossways, and can still be parked independently.

The Combilift 543 offers parking spaces on three levels with just one lane.

-

Surface area

Width 19,05 m x length 33,70 m at approx. 642 m²

-

Underground levels

3

-

Parking spaces Combilift

34

-

Parking spaces Conventional underground car park

39

-

Parking Space Parking system

Length 5,70 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

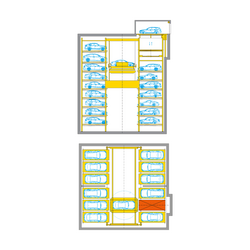

COMBILIFT 543 MR

With the ‘Combilift 543MR’, the vehicles are stored in an extremely compact way by raising, lowering and moving the parking pallets sideways, and can still be parked independently on 3 levels.

Thanks to the ‘Multi Row’ function of the MR version, the systems and therefore also the vehicles can be arranged in multiple rows. The flexible MR sliding platform acts as a bridge and enables access to the rear row of the parking system.

-

Surface area

Width 24,85 m x length 33,70 m at approx. 837 m²

-

Underground levels

3

-

Parking spaces Combilift

67

-

Parking spaces Conventional underground car park

60

-

Parking Space Parking system

Length 5,70 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

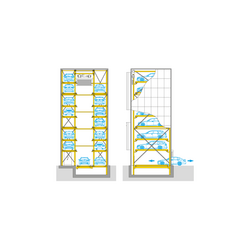

COMBIPARKER 560 - NEW!

The ´Combiparker 560´ is comparable to the Combilift and also offers the possibility of storing vehicles in an extremely compact way by raising, lowering and

and moving the parking pallets crossways.

However, thanks to a special technology, the Combiparker 560 allows cars to be parked on up to 5 levels - with just one parking level.

-

Surface area

Width 19,05 m x length 33,70 m at approx. 642 m²

-

Underground levels

5

-

Parking spaces Combiparker

58

-

Parking spaces Conventional underground car park

63

-

Parking Space Parking system

Length 6,00 m, width 2,70 m, height 2,05 m

-

Parking space conventional

Length 5,20 m, width 2,65 m

Information about the individual parameters that were included in the calculation.

View details

Energy consumption

- Excavator (EURO6) for excavation: 0.00062 MJ/kg

- Reinforced concrete (concrete foundation, concrete surface, concrete ceiling, ramp,

masonry): 2.48 MJ/kg - Wall cladding: 7.98 MJ/kg

- Waterproofing: 97.00 MJ/kg

- Car park ventilation: 71.89 MJ/kg

- Fire safety systems: 41.49 MJ/kg

- Electrical installations: 75.30 MJ/kg

- Parking system: 25.42 MJ/kg

Material use

- Excavator for excavation

- Reinforced concrete (concrete foundation, concrete surface, concrete ceiling, ramp,

masonry): - Wall cladding

- Waterproofing

- Underground car park installations

- Parking system including assembly

Emissions

Construction pit:

- Excavation/excavator: 0.00005 kg CO2/kg

- Reinforced concrete (concrete foundation, concrete surface, concrete ceiling, ramp,

masonry): 0.23 kg CO2/kg - Wall cladding: 0.37 kg CO2/kg

- Waterproofing: 3.00 kg CO2/kg

- Car park ventilation: 2.45 kg CO2/kg

- Fire safety systems: 4.71 kg CO2/kg

- Electrical installations: 2.43 kg CO2/kg

- Parking system: 1.72 kg CO2/kg

Costs

Approx. costs per m2 for conventional car park

1st level = € 800 per m2

2nd level = € 1,000 per m2

3rd level = € 1,200 per m2

Note: The comparison is based on costs in the Munich area.

Detailed comparison report of two construction pits:

- Introduction: This report aims to make a detailed comparison between two construction pits, analysing the excavation and transport processes. In case one, the construction pit has a volume of 3605 m3, while in case two, the construction pit has a volume of 4379 m3. The aim is to work out the differences in excavation time, transport time, CO2 emissions and savings between the two scenarios.

- Methodology: The data for this report comes from a variety of sources, including industry standards, manufacturer information and real-world experience. The calculations are based on this data plus standardised formulas and assumptions that are widely used in the construction industry.

- Excavation process: The construction pit is dug out using an excavator. The excavator has a bucket capacity of 2 m3. The excavation time is determined by the number of bucket passes required.

Wöhr Green Parking

Green Parking is the WÖHR sustainability initiative.

If you have any questions and comments or would like to learn more about our products, don’t hesitate to contact us. We look forward to hearing from you!